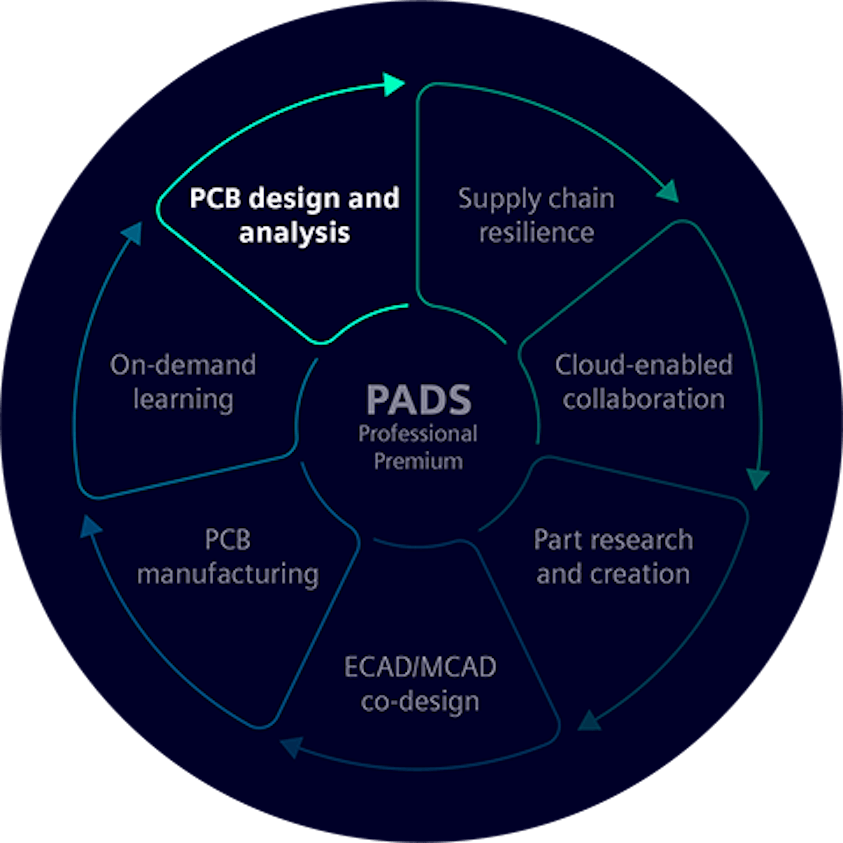

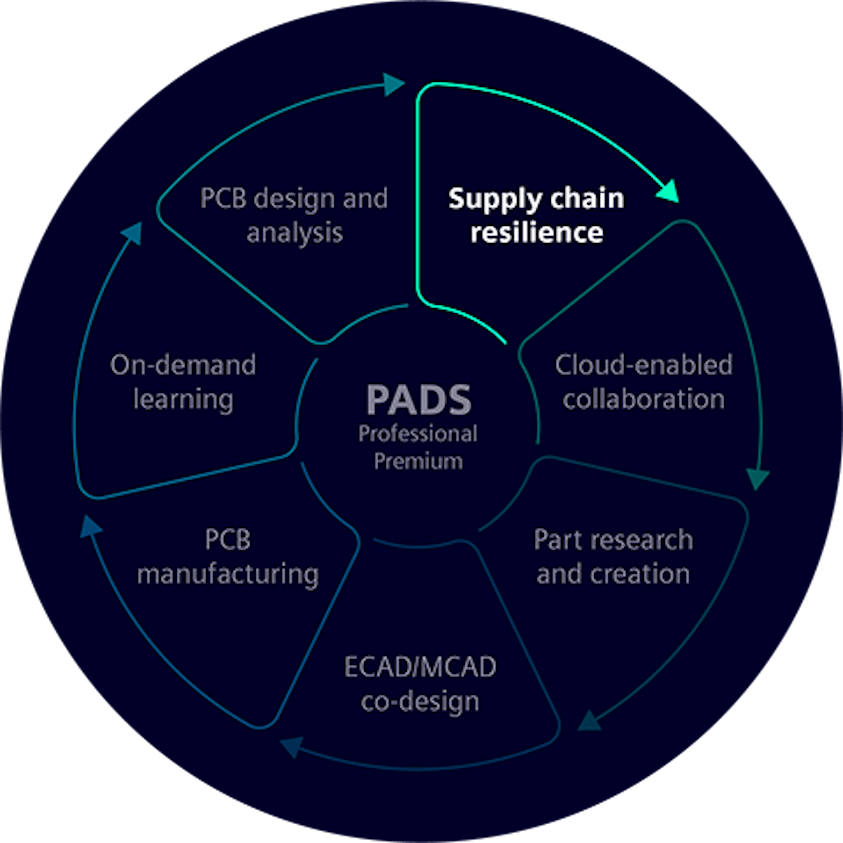

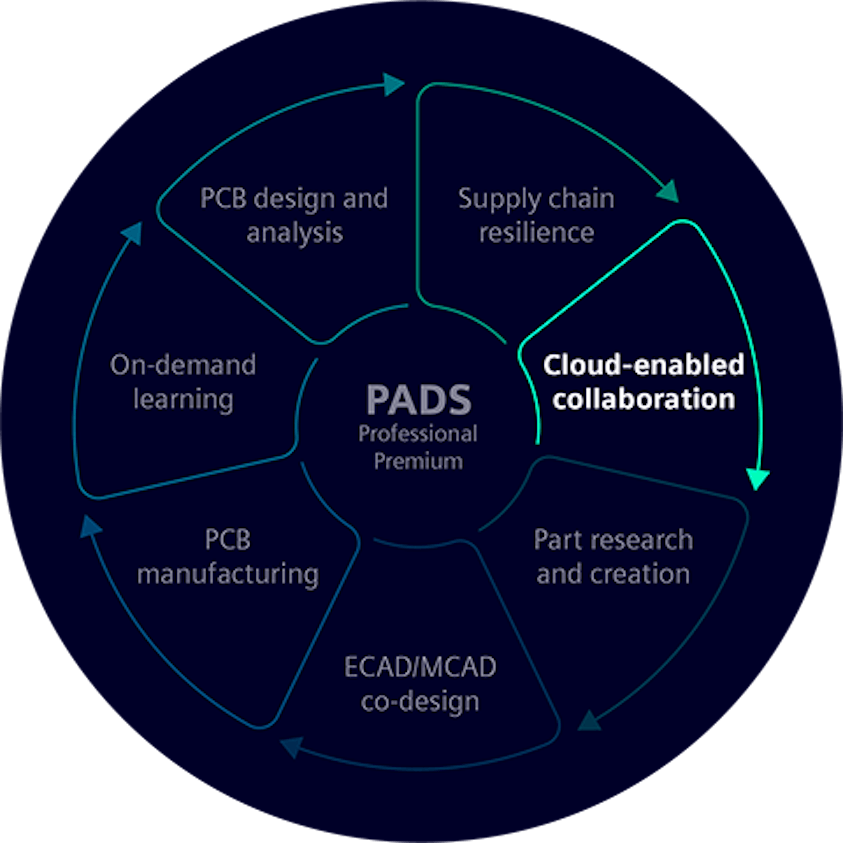

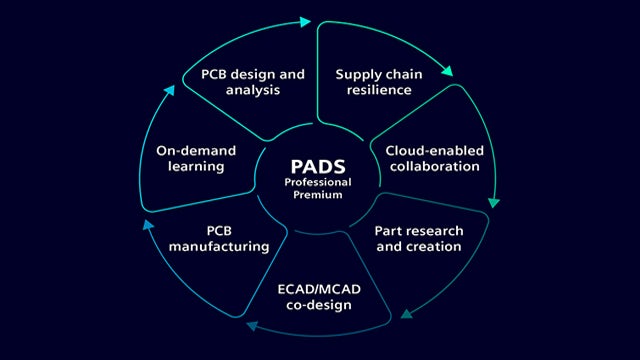

PADS Professional Premium delivers everything you need to design your simplest to most complex PCB designs. Full function, yet easy to use, with features and technologies like:

- Routing automation

- Rigid-flex

- RF design

- Analog/mixed-signal simulation

- Signal integrity analysis